Canopy covers of all kinds and large-format printing from Hodonín.

Your reliable partner for more than 30 years in the Czech Republic and Slovakia.

More about us

years on the market

satisfied clients

projects

Material outages? We don't know that here

We founded Lubor Dubšík and TIREX in 1991. We started with the production and repair of car sails. And over time, we expanded our activity to include the production of advertising. Car covers were still being sewn at that time. But we were well aware that we would not save the world by doing so. That's why we weren't afraid of the onset of modern times and bought new technologies.

What materials do we use?

Our implementation.

Vehicle covers and prints from us are guaranteed not to disappoint you.

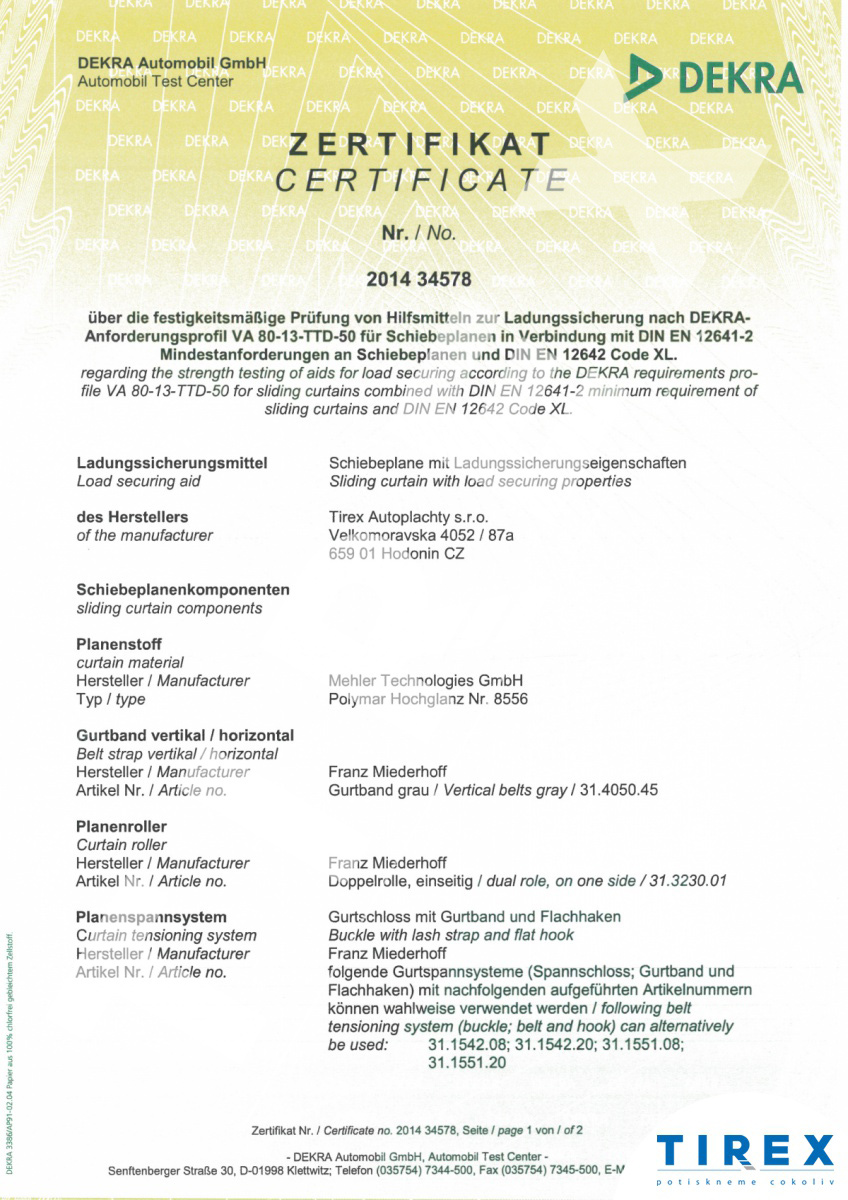

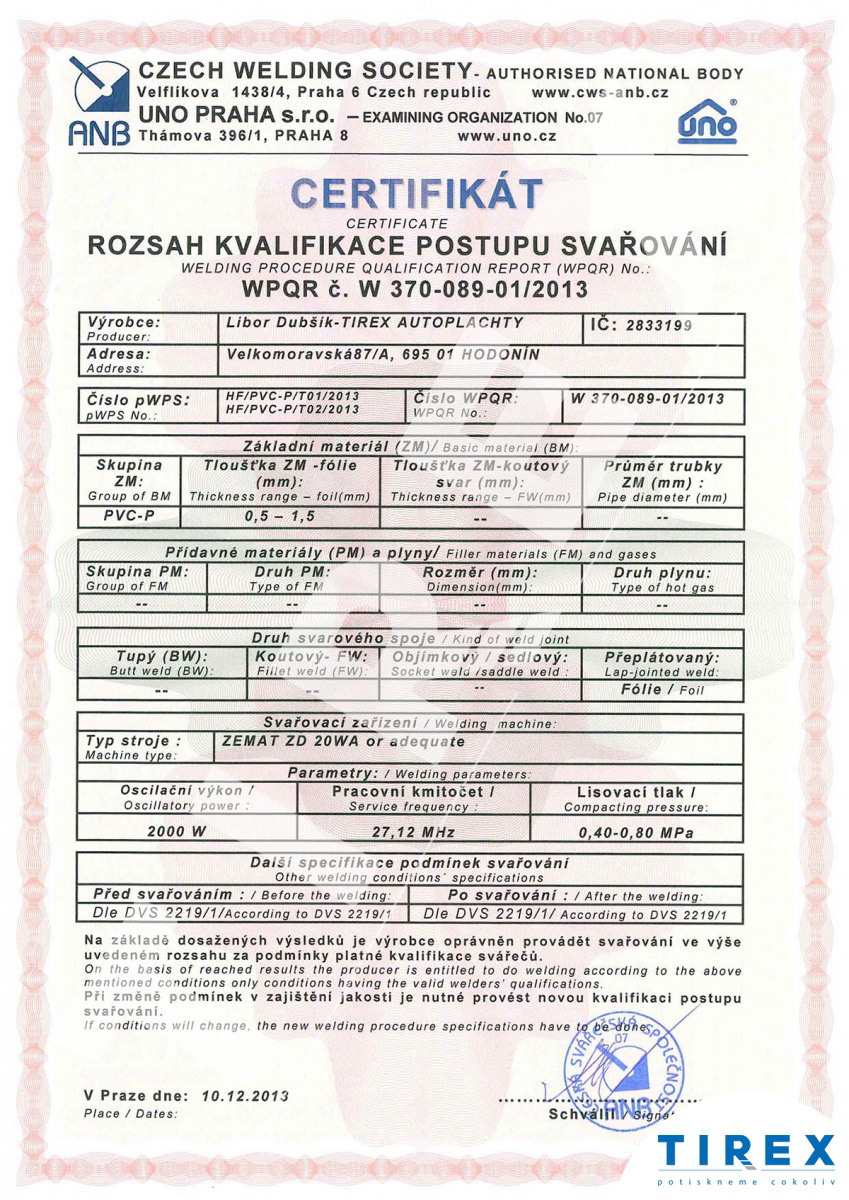

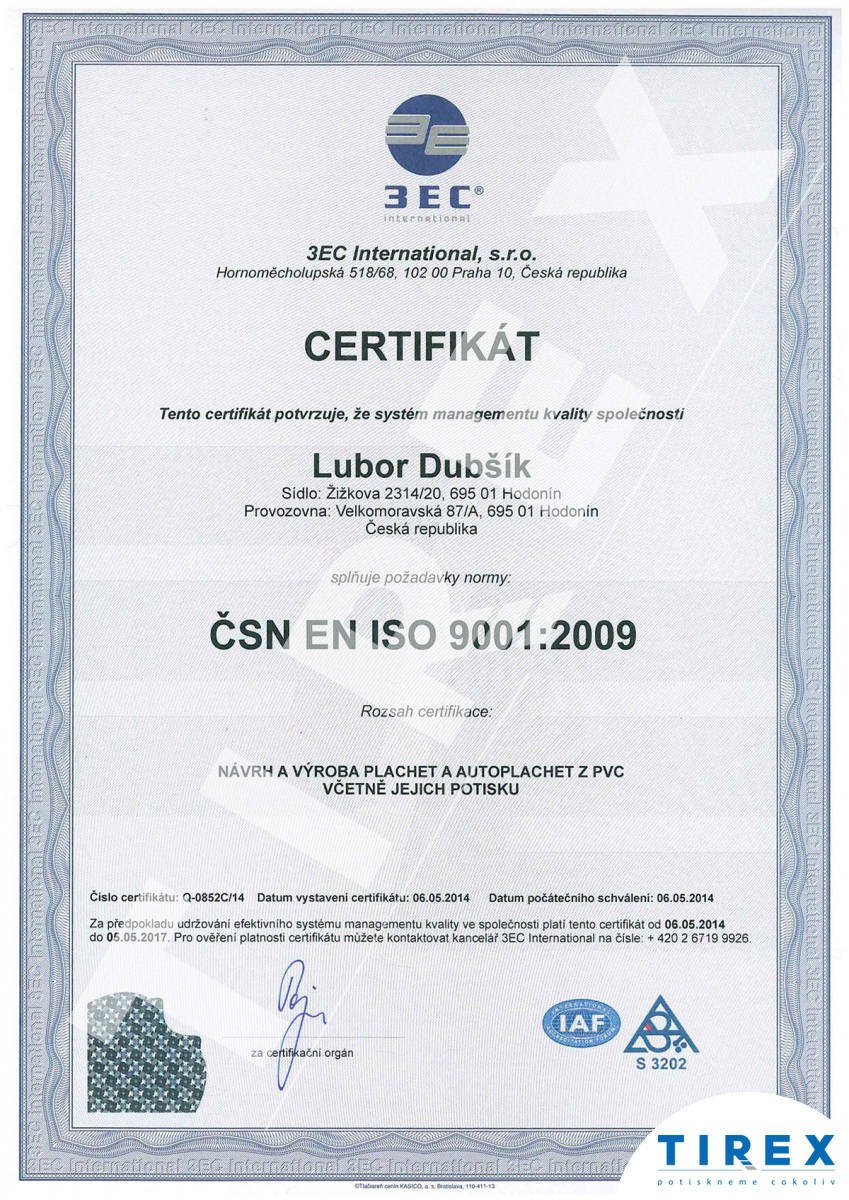

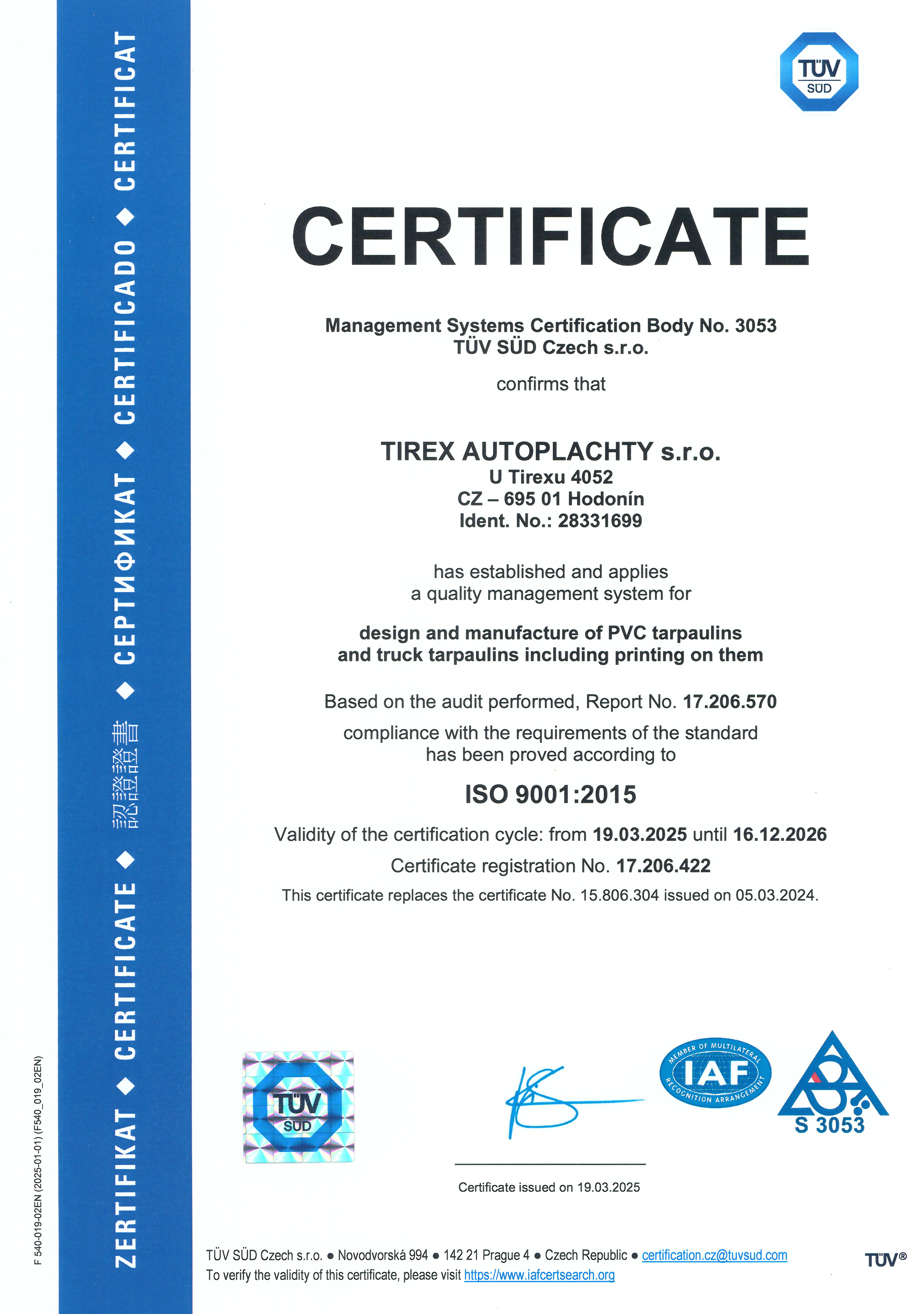

We are professionals.

And we have it officially confirmed.

Our partners

We support

EU Projects

The Ministry of Industry and Trade as the governing body of the Operational Program Entrepreneurship and Innovation for Competitiveness (hereinafter referred to as the "subsidy provider" or "MPO") based on the request for a subsidy under the Real Estate Call - Call VI of the REAL ESTATE support program - HELP AFTER THE TORNADO - activity A VI. Challenge - Help after the tornado (hereinafter referred to as the "Challenge") and Priority Axis PO-2 "Development of business and competitiveness of small and medium-sized enterprises of our company LUBOR DUBŠÍK after the tornado natural disaster of 6/24/2021 provided financial support from the European Union. The goal of the project is the restoration of the damaged buildings of the premises of the company Lubor Dubšík - production and administrative premises of the buildings on Velkomoravská street, 695 01 Hodonín no. 4052/87a, and part of the building No. 3543/87.

Read more